Pressure Canning Process Controller

The project converts a stovetop pressure cooker/canner into a fully automated pressure processing system with the addition of a few inexpensive components. It can accurately monitors and controls the pressuring process.

Using a Renesas M16C microcontroller, the system can control the entire process using an ordinary off-the-shelf pressure cooker/canner and portable electric coil burner. Once the process has been setup, this controller allows you to walk away from the burner and return when the jars have been sealed. The entire canning process has been simplified with the addition of this controller. With a fully variable programmable function and auto-tune, the system controls and regulates the process pressure with extreme simplicity and accuracy. With such versatility, the controller can also be used to cook meats and vegetables for today’s meals using the same pressure process.

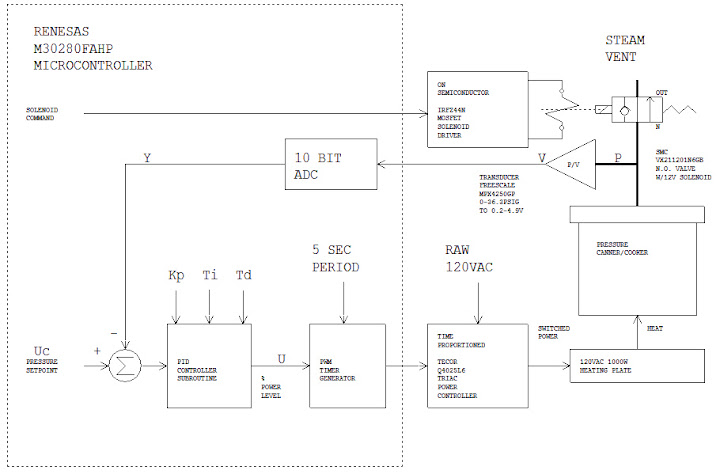

The figure below shows a simplistic block diagram of the system. Adjusting the amount of heat input regulates the pressure inside the vessel. Simply put, when the vessel is heated, the pressure inside rises and when the vessel is allowed to cool, the pressure inside drops. A heating plate is used to apply heat to the canning vessel. These heating plates can be purchased at most hardware or department stores. The heating plate used in this system is 1000W single coil unit. Only a single coil unit should be used.

The canner used in the design of this system has a 17-quart volume. Other size canners may be used because the software has an auto-tuning feature built in. A valve/vent-pipe assembly that has been fabricated is located atop the canning vessel. This assembly allows venting steam to atmosphere and closing the volume during the process. It also has a Freescale MPX-4250GP pressure sensor that converts the range of 0 to 36.3PSIG to 0.2 to 4.9VDC. This transducer measures the feedback pressure from the inside of the vessel during the process. It provides a conditioned output that is fed to the 10 bit Analog to Digital Converter inside the Renesas processor. An output from the Renesas processor is fed to a MOSFET driver (On Semiconductor IRFZ44N) which controls the state of the vent valve solenoid.

The Hot Plate receives switched power from a Tecor Q4025L6 Triac. The triac is fed RAW AC from the mains. It is controlled through an optically isolated On Semiconductor MOC3042 by a time proportioned ON/OFF signal from the Renesas microcontroller (PWM Output). The period of this signal is 5 seconds. The heating effect of the hot plate is produced by time proportioning the applied power. A PID algorithm is used once each second to calculate the PERCENT of POWER output required during the regulation phase of the process. The diagram below shows how the gate signal turns on the triac and allows it to pass AC current to the HEATING PLATE. The project is designed by Gregory Ciavattone.

Pressure Canning Process Controller

Project Firmware, Schematic and Documentation

circuitcellar.com