Automatic Pet Fountain

The goal of project was to keep the water bowl full and keeping the dog and cat watered at all times without flooding the house. It gets its water supply from an ice maker water line. Phillip Moorman built this project based on Parallax.

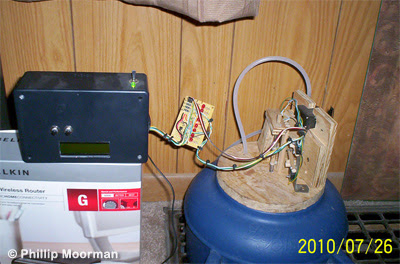

He built a float and water valve assembly that fits on the water bowl in place of the original 5 gallon water jug. He built what He call a logic board that consists of eight LED’s, four expansion headers, and a transistor that supplies the ground for the switches and LED’s. The board allows him to visually see what is going on with the switches and provides a connection for the servo and anything else that uses a 3 wire connection.

The control box is built using a Board of Education and a BS2. It includes two push buttons and a serial LCD display. It is powered by a 12v wall wart. The project features a battery backup circuit into the control box to prevent flooding if the power went out during a refill cycle. The program first checks the power status and if it finds that it is running on battery power, it closes the water valve if open and shuts the system down. It then goes to sleep for about an hour and then rechecks for main power. If main power returns, it goes back to normal operation.

It checks the status of the valve and float switches along with power status about every 5 seconds and if the float is in the empty position it automatically refills the bowl. If for some reason during the refill cycle a switch fails on the float, it times out, close the water valve and blink the logic board LED’s until reset to alert someone of a problem.

The program also includes a main menu for the LCD consisting of “Run”, “Maintenance”, “History”, and “Diagnostic”. In the maintenance menu it allows user to lock the system, so user can remove it from the bowl for cleaning without flooding the house. User can then reset the refill counter when unlocking the system for normal service. In the history menu it displays how many times it has refilled itself between cleanings and how many times since a hard reset. Phillip wrote the program to write the lifetime refills to EEPROM, but have not decided to allow it yet, so the required code to do so is commented out. The diagnostic menu provides the ability to manually open and close the water valve and the ability to manually check the float operation by observing the LED’s on the logic board.